Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

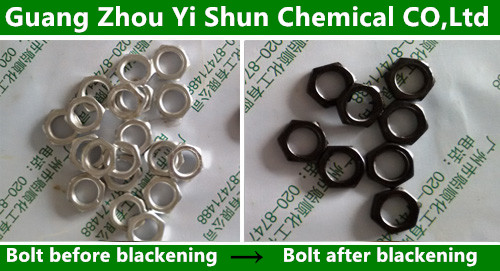

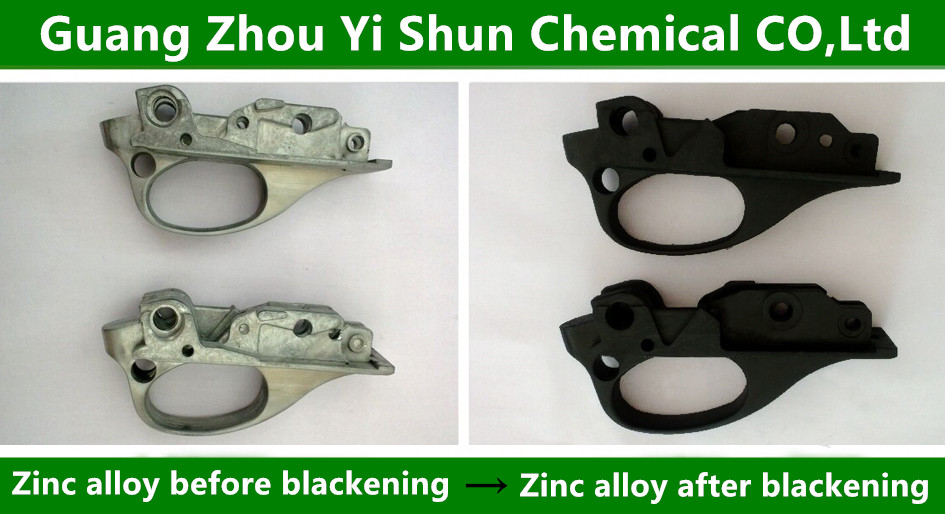

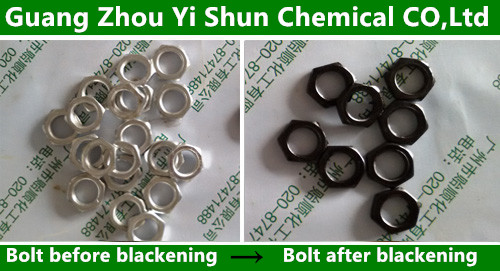

Product Name:Environmental protection and chromium free black zinc passivating agent at normal temperature,Zinc archaize agent,Zinc fast blackening agent

Price:

Environmental protection and chromium free black zinc passivating agent at normal temperature,Zinc archaize agent,,Zinc fast blackening agent, Environmental protection and chromium free black zinc passivating agent at normal temperature,Zinc archaize agent,Zinc fast blackening agent First,Product Code: Q/YS.504-2 (Yi Shun brand) Second, product advantages: This product is free of trivalent chromium and hexavalent chromium. The passivation film of zinc layer is compact, easy to operate, and the working environment is clean and hygienic. The product is nearly neutral, almost no irritation to the skin, non-toxic environmental protection, strong resistance to corrosion membranes, and resistance to neutral salt spray tests for more than 300 hours. Third, the scope of application: Widely used in zinc plating and zinc alloy passivation, passivation film layer is black, suitable for rack plating, barrel plating, screws, automotive motorcycle accessories and other most urgent designated items. Fourth, product indicators: 1. Product appearance: odorless, light blue transparent liquid 2.Specific gravity: 1.02~1.03 3.PH value: 3.0 to 7.0 (partial neutrality) Fifth,How to use: 1.The product can be used after adding 1 times tap water and working fluid. 2.Soak the galvanized workpiece in 3% nitric acid for 3 seconds and the workpiece will shine. (It is best to use the company's special light agent, do not hurt the zinc layer) 3.After the galvanized part is put into the black zinc passivator immediately after the water wash, the passivation film is black after 30 seconds to 60 seconds. 4.Closed membrane: After immersing the sealant for 2 minutes, wash it again. 5.Dry the workpiece after washing and dry it at 50°C for half an hour. Other processing:Zinc surface treatment agent series、Zinc blackening agent、Stainless steel remover for removing oil and rust、Environmental degreaser and rust remover

|

Chinese

Chinese English

English