Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

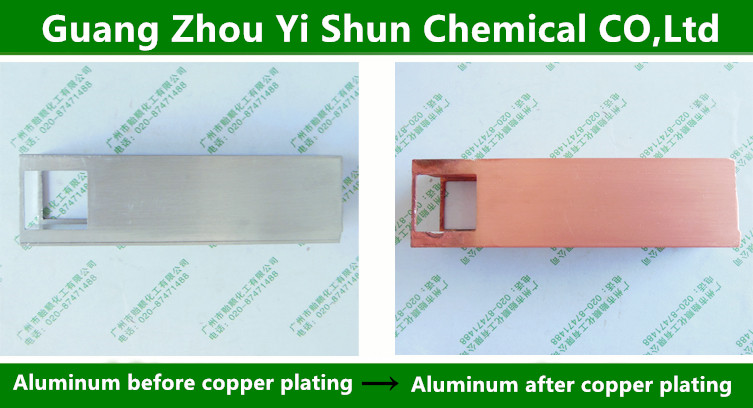

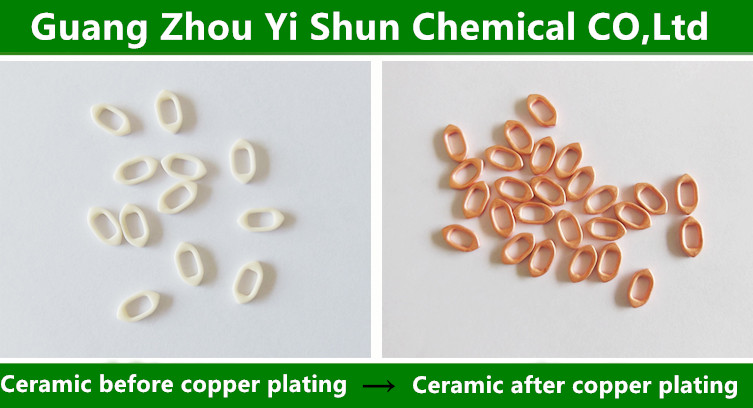

Product Name:Unscented and environmental chemical copper plating liquid, rapidly copper plating agent, New chemical copper plating liquid, chemical copper sealing agent, Electroless copper protective agent,Anti-oxidation copper blunt fluid

Price:

unscented and environmental chemical copper plating liquid, rapidly copper plating agent, New chemical copper plating liquid, environmental copper plating liquid medicine, chemical copper sealing agent, Electroless copper protective agent,Anti-oxidation copper blunt fluid,Environmental protection copper protective agent Unscented and environmental chemical copper plating liquid, rapidly copper plating agent, New chemical copper plating liquid, chemical copper sealing agent, Electroless copper protective agent,Anti-oxidation copper blunt fluid First, the product code: Q / YS.148 (Yi Shun brand) Second, product performance: This product has high speed sink copper, high stability, working temperature and solution concentration for a wide range of applications. Copper layer is dense, with excellent bonding, the coating is bright copper color, 45 ℃ under the coating speed of 20 microns / hour. This product is environmentally friendly odorless, adapted to cleaner production, is a new type of chemical copper plating solution. Third, the product scope: This product is suitable for printed circuit board hole metal, aluminum, iron, steel, stainless steel and copper alloy surface copper plating, suitable for hanging baskets chemical plating. Also suitable for ceramic copper, glass copper, resin copper, plastic copper, diamond copper, leaf copper, etc., a very wide range of uses. Does not contain formaldehyde, completely environmental odorless, non-toxic and harmless. Fourth, product index: This product consists of A, B, C three components: ① High-speed copper agent A agent: the proportion of 1.10 to 1.12, blue liquid, odorless. ② Shen copper B agent: the proportion of 1.10 ~ 1.12, transparent liquid. PH value of 13 to 14, odorless. ③ Shen copper C agent: yellow liquid, odorless, neutral. ④ Copper working fluid preparation: before use according to A: B: C: water = 1: 4: 1: 4, the preparation order is: first prepare 4 parts of water, then add 1 part of A, then add 1 part C , Finally add 4 copies of B, stir well. (Note: clean tap water is ok) ⑤ Sinking copper process: pre-treatment workpiece ---- washed --- copper sink (5 minutes -40 minutes) --- washing --- passivation --- drying. A. For iron surface and nickel surface and silver surface copper plating, just pickling rust can be used for copper. B. For zinc alloy surface, it is necessary to use zinc polishing agent or zinc degreasing agent to degrease and brightly treat it, then pre-plating with zinc alloy special copper plating liquid, and thickening copper plating with this product (Q / YS.148). C. For stainless steel, degreasing first with hydrochloric acid for 3 minutes, and then use the company's special stainless steel copper plating liquid(Q / YS.129) pre-plated copper, and then use chemical copper plating liquid (Q / YS.148) for thickening copper. D. For non-metallic (ceramics, glass, diamond, sand, etc.) should be roughened → washing → sensitization → hot water washing → activation → washing → copper plating; also roughening → activation → nickel → copper plating. Fifth, note: ①copper sinking process will continue to consume ingredients, copper sinking process should be promptly added A and C and sodium hydroxide, test and adjust the PH value to 12.5 ~ 13.0. (Adding A under stirring, slowly adding 20% sodium hydroxide solution, and then adding C agent) ②copper loading than 1 ~ 3d㎡, copper temperature: 35-50 ℃, water bath insulation. ③chemical copper sink to stop working, we must continue to maintain air mixing, with 20% sulfuric acid to adjust the PH value to 9 to 10, the bath to be covered to prevent active ingredients of the bath of reactive power loss and insect dust pollution. Restart the bath, you can use 20% NaOH under stirring to adjust the PH value to 12.5 ~ 13.0 ④ in the process of sinking copper if found plating becomes cloudy, this time to stabilize 0.5 g / l. Stir the bath back to stability. ⑤after the end of copper plating, use water to clean, and then soaked in hot water at 80 ℃ -90 ℃ for several minutes, and timely follow-up treatment, such as passivation or plating other metal layer. Especially for porous materials, it should be cleaned several times, and washed thoroughly with hot water to ensure the smooth follow-up of the workpiece, such as ceramic, wood, cotton absorbent materials. Other processing:Chemical Plating Liquid Train、Copper oil removal passivation agent、Inferior quality brass environmental chemical polishing agent、Environment-friendly copper chemical polishing liquid

|

Chinese

Chinese English

English