Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

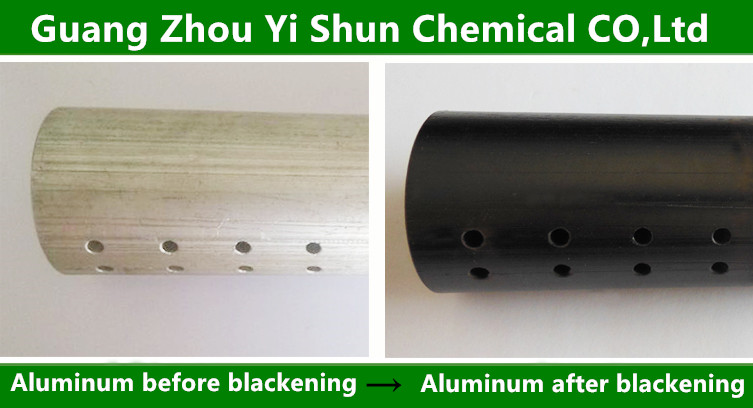

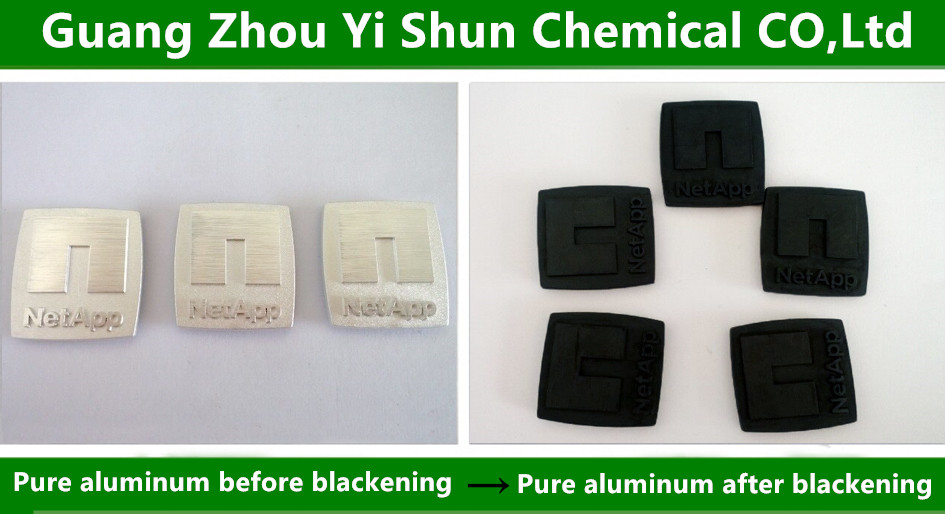

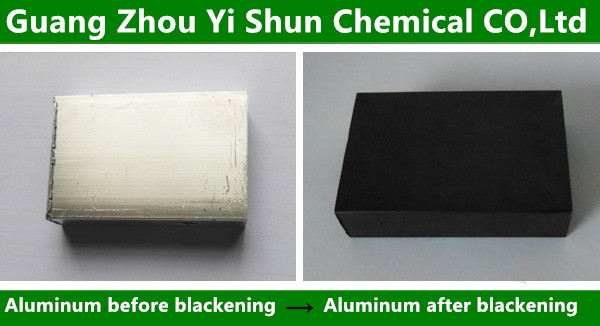

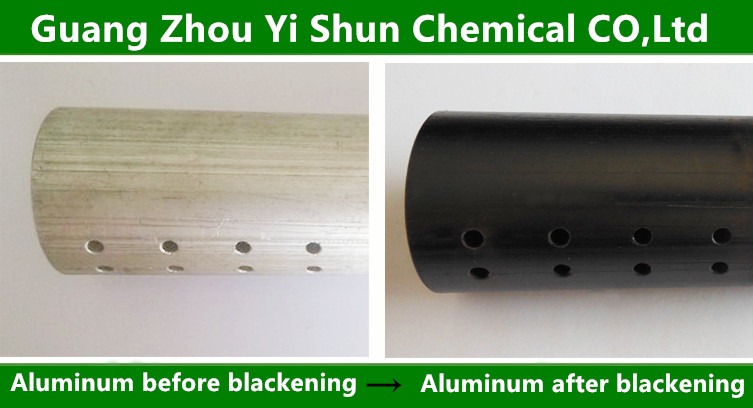

Product Name:Aluminum Blackening Agent,Aluminum Parts Blackening,Aluminum Alloy Blackening

Price:

Aluminum Blackening Agent,Aluminum Parts Blackening,Aluminum Alloy Blackening Aluminum Blackening Agent,Aluminum Parts Blackening,Aluminum Alloy Blackening 1. Product number: Q/YS.207 (Yi Shun brand) 2. Range of application: This product can be widely used for blackening of blunt aluminum, aluminum alloy, aluminum die casting, aluminum magnesium alloy surface. It make surface of the aluminum alloy form a layer of black compact oxide film. The film has a high corrosion resistance and excellent wear resistance. The black film is uniform and has a good decorative effect. Product is odorless, environment friendly, non-toxic and beneficial to the clean production. 3. Product index: ⑴ Light yellow (colorless) transparent liquid, odorless. ⑵ Proportion:1.02-1.04. ⑶ PH value: 6-8 neutral solution. Note: pre-impregnated oxidant: specific gravity 1.1~1.15. 4. Usage process Degreasing, removing oil and removing oxide of aluminum→polishing and washing→ Pre-treatment of A agent for 8-30 seconds at room temperature→washing→ Pre-treatment of B agent for 8 seconds at room temperature→washing→ Pre-treatment of A agent for 8 seconds at room temperature→Blackening agent is added 1 times of water at 90℃~100℃ for 5 minutes→washing→drying→finished product 5. Matters needing attention: ⑴Blackening temperature is at 90℃~100℃, or heating with available electric heating tube. ⑵Only if making pre-treatment before blackening, you can proceed to the next step, and at the same time the surface of the work piece should be uniform. ⑶In order to keep the stability of black potion effect, supply 5%~10%of blackening agent solution. ⑷The sediment of blackening at the bottom is cleaned up timely. Other processing:Aluminum surface treatment agent series、The copper surface is chemically coated with black metal film、Cast Aluminum Cleaning Agent、Environmental protection chemical plating nickel liquid (super-concentrated)、Gold colorant of aluminum、Zinc coating imitation gold agent

|

Chinese

Chinese English

English