- Chemical Plating Liqui¡

- Environmentally friend¡

- Copper surface treatme¡

- Aluminum surface treat¡

- Iron and steel surface¡

- Tin surface treatment ¡

- Zinc surface treatment¡

- Nickel surface treatme¡

- Industrial cleaning ag¡

- Domestic cleaning agen¡

- Magnesium surface trea¡

- Other metal surface tr¡

- Other

Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

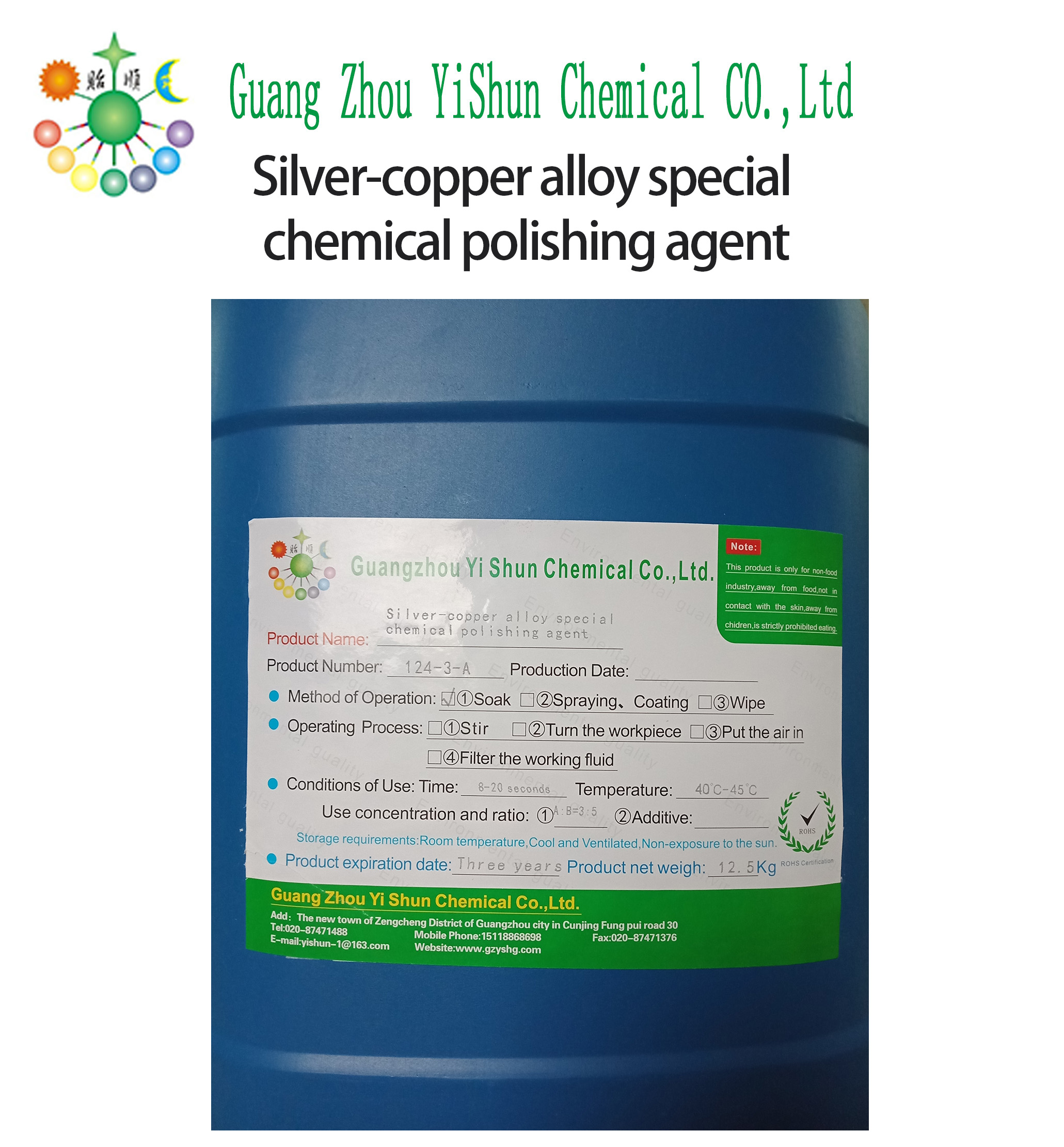

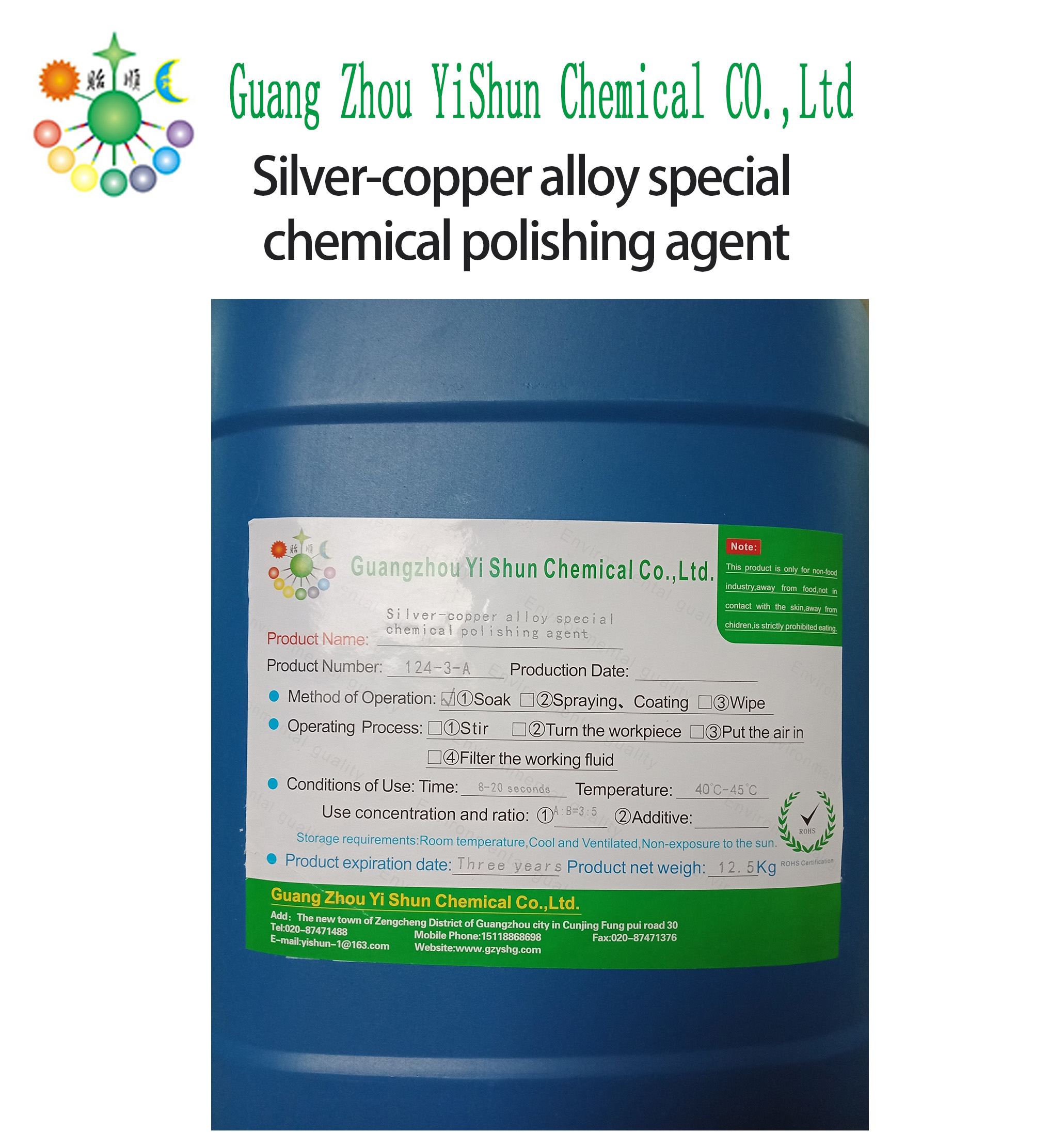

Product Name£ºSilver-copper alloy special chemical polishing agent£¬Silver-copper polishing agent£¬Silver-copper brightener£¬Environmentally friendly chemical polishing liquid£¬Silver-copper cleaning and polishing agent

Price£º

Silver-copper alloy special chemical polishing agent£¬Silver-copper polishing agent£¬Silver-copper brightener£¬Environmentally friendly chemical polishing liquid£¬Silver-copper cleaning and polishing agent£¬Chemical copper polishing cleaner Silver-copper alloy special chemical polishing agent£¬Silver-copper polishing agent£¬Silver-copper brightener£¬Environmentally friendly chemical polishing liquid£¬Silver-copper cleaning and polishing agent product number :Q/YS.124-3 (yishun brand) Usage: this product is a unique formula. Environmental protection, no smoke and no smell. This product is only used for the chemical polishing of silver-copper alloy, high brightness, no yellow smoke, no hexavalent chromium and other harmful substances, environmental protection and non-toxic, quick and simple operation, can quickly get rid of stubborn oxide skin, the mirror white bright effect. Product indicators (1)Yellowish odorless liquid (2) PH value: acidic products (3) proportion: >1 Operation method: (1) The product has A agent and B agent of two components, the volume ratio of A:B=3:5 configured as A working fluid. (2) the oil removal after silver copper alloy workpiece immersion in polishing working liquid, (40 ¡æ - 45 ¡æ) leaching 8 to 20 seconds, remove the artifacts, clean into clean water immediately. (3) silver copper chromium-free passivation color retention passivation for 5 minutes. (4) water washing (5) drying the workpiece Matters needing attention: (1) there will be loss in the use of the product, midway to supplement A and B agent. Generally, agent A is supplemented with 10% of the tank volume, while agent B is supplemented with 5% of the tank volume. (2) when the tank ion concentration is too high, polishing effect obviously decreased, then to do scrap processing. (3) waste solution treatment: with stone powder (calcium carbonate) and polishing waste solution, adjust PH=8~9, and then sedimentation, recovery of silver and copper slag, wastewater can be discharged. Other processing£ºEnvironmental degreer and rust remover¡¢Stainless Steel Polishing Agentas¡¢Brass Green Chemical polishing Agent¡¢Electroless plating of real gold on copper surface¡¢Strong oil stain removal agent¡¢Environmental non-cyanide gold removal liquid

|

Chinese

Chinese English

English