Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

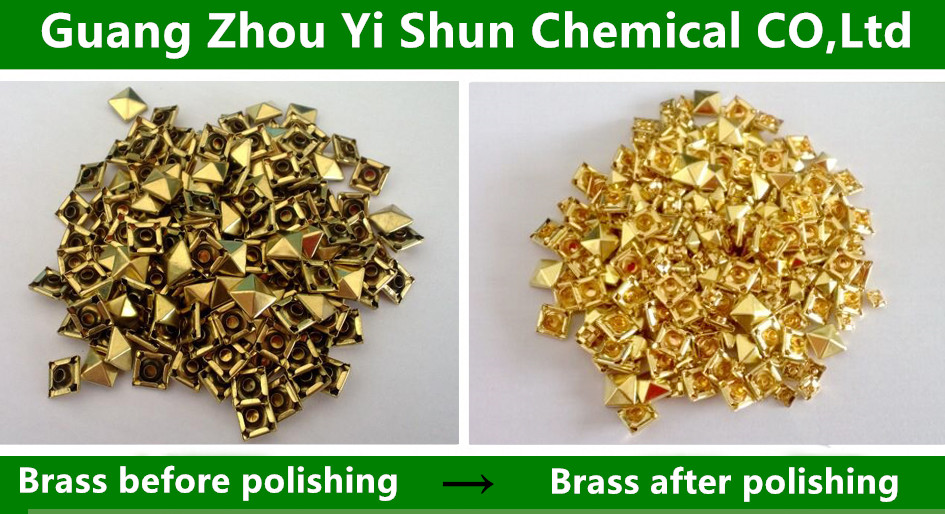

Product Name:Spraying Type copper polishing agent,Chemical polishing Agent,Polishing Agent,Environmental protection polish liquid, Rapid effect polish soulution

Price:

Spraying Type copper polishing agent,Chemical polishing Agent,Polishing Agent,Environmental protection polish liquid, Rapid effect polish soulution Spraying Type copper polishing agent,Chemical polishing Agent,Polishing Agent,Environmental protection polish liquid, Rapid effect polish soulution First, the product code: Q / YS.111 (Yi Shun brand) Second, the product range: This product is suitable for brass, copper, oxygen-free copper, copper, beryllium copper polishing and renovation, especially for large bronze, large copper parts, large copper nameplate and other large copper parts, copper Polished and refurbished products, this product has the advantages of simple operation, saving time and labor, fast economy and excellent effect. No yellow smoke when using. Third, product index: ① Proportion :1.46 ~ 1.50, ② PH value: acidic product. ③ Appearance: yellowish transparent liquid. . ④ Do not add any heavy metals, non-hexavalent chromium. Fourth, product use method: ① The use of product stock solution, non-adding water or workpiece with water into the polishing liquid, also do not allow the use of the polishing liquid and fresh slurry mixed use. ② Before using the latex gloves, you can use a clean dry towel or brush to adhere to the polishing liquid, coating the surface of the copper workpiece, the entire workpiece after coating, after 10 to 30 seconds, fully rinse the workpiece with water . ③ You can also put the polishing liquid into the watering can with the pump head while spraying the polishing liquid on the surface of the copper workpiece while applying the polishing liquid evenly with a dry towel or brush. After 10 ~ 30 seconds rinse thoroughly with water. ④ The workpiece can also be immersed in the product solution 10 to 80 seconds, and then remove the workpiece in the air to stop 10 to 30 seconds, and then washed. ⑤ Copper parts after cleaning to be passivated color retention treatment or other (such as: varnish, etc.). Fifth, note: ① Liquid use, non-add water. ② The product can not be exposed, please store in a cool and ventilated place. And sealed to store. ③ Copper workpiece before polishing, the surface can not have oil, if oil, you must first remove the oil on the copper workpiece decontamination. Other processing:Stainless Steel Polishing Agentas、Brass Green Chemical polishing Agent、Electroless plating of real gold on copper surface、Strong oil stain removal agent、Environmental non-cyanide gold removal liquid、Copper chromium-free passivation agent

|

Chinese

Chinese English

English