Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

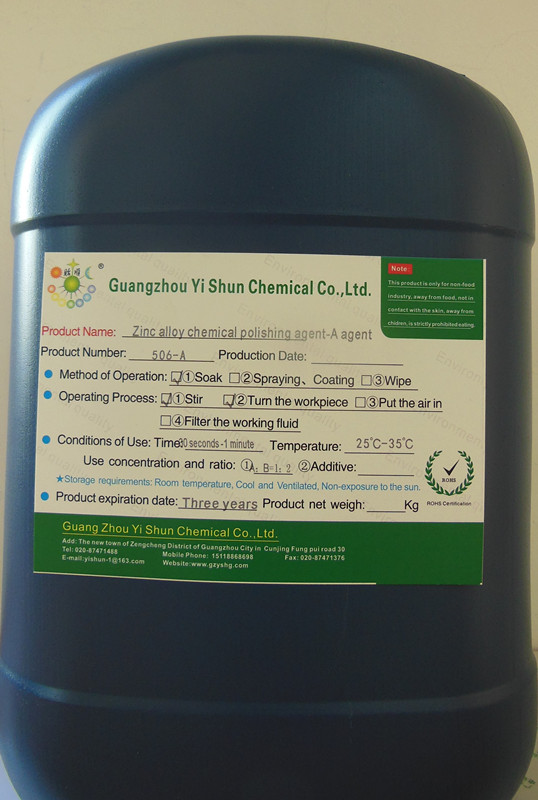

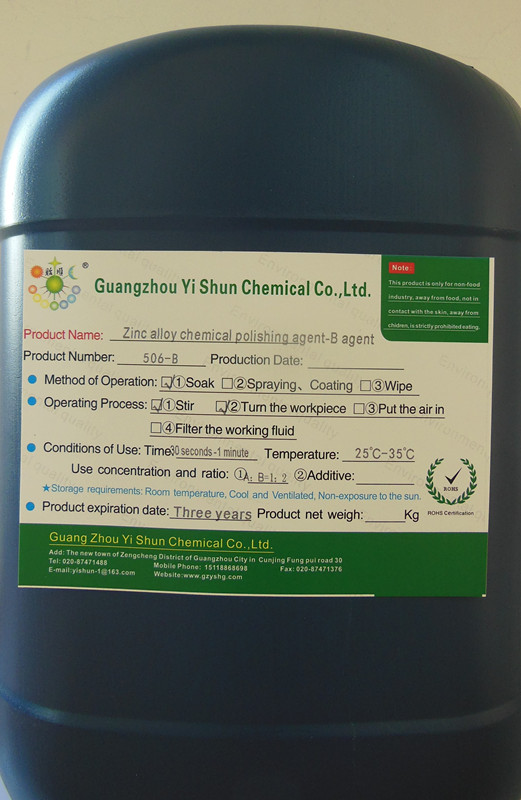

Product Name:Zinc alloy chemical polishing agent,chemical polishing solution, zinc brightening agent , zinc alloy protective agent, antioxidant water for polishing and removing rust

Price:

Zinc alloy chemical polishing agent,chemical polishing solution, zinc brightening agent , zinc alloy protective agent, antioxidant water for polishing and removing rust Zinc alloy chemical polishing agent,chemical polishing solution, zinc brightening agent , zinc alloy protective agent, antioxidant water for polishing and removing rust (I) product no. : Q/YS.506-2 (yishun brand) (ii) scope of application: This product is widely used to polish the surface of all kinds of zinc alloy die castings. Simple operation, room temperature use, just soak. Suitable for all kinds of zinc alloy treatment and bright treatment before plating. (iii) product indicators: 1. Transparent liquid, free of heavy metal, composed of two agents, AB. 2. Specific gravity > 1.2 Acidic products have a slight smell (iv) usage: mix C by volume ratio A:B: water = 1:1:2-3, or by weight ratio A:B: water = 5:6:8-9 1. Remove oil and scale of zinc alloy. 2. Zinc alloy polishing: soak the clean zinc alloy in the chemical polishing liquid of zinc alloy for about 30-1 minute, and turn the workpiece immediately, remove the workpiece, and immediately put it in water to rinse. 3. Dry the zinc alloy workpiece (v) matters needing attention: 1, the products according to the proportion ratio, polishing temperature control between 20 ~ 40 ℃. 2. Add A and B in proportion in the middle of use to restore the effect. 3. The product is corrosive and operated with adhesive gloves. 4. Wash the zinc workpiece immediately after it is taken out from the polishing process. Lest affect glossiness. Clean the water in the pool to replace in time, too high residue will affect the gloss. Other processing:Environmental degreer and rust remover、Brass Green Chemical polishing Agent、Electroless plating of real gold on copper surface、Strong oil stain removal agent、Copper、chromium and nickel stripping agent

|

Chinese

Chinese English

English