- Chemical Plating Liquiíş

- Environmentally friendíş

- Copper surface treatmeíş

- Aluminum surface treatíş

- Iron and steel surfaceíş

- Tin surface treatment íş

- Zinc surface treatmentíş

- Nickel surface treatmeíş

- Industrial cleaning agíş

- Domestic cleaning ageníş

- Magnesium surface treaíş

- Other metal surface tríş

- Other

Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

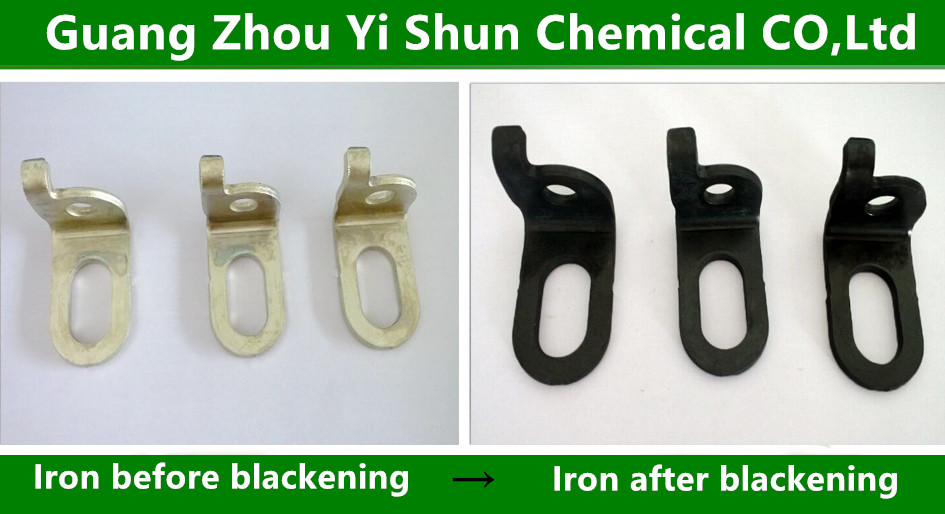

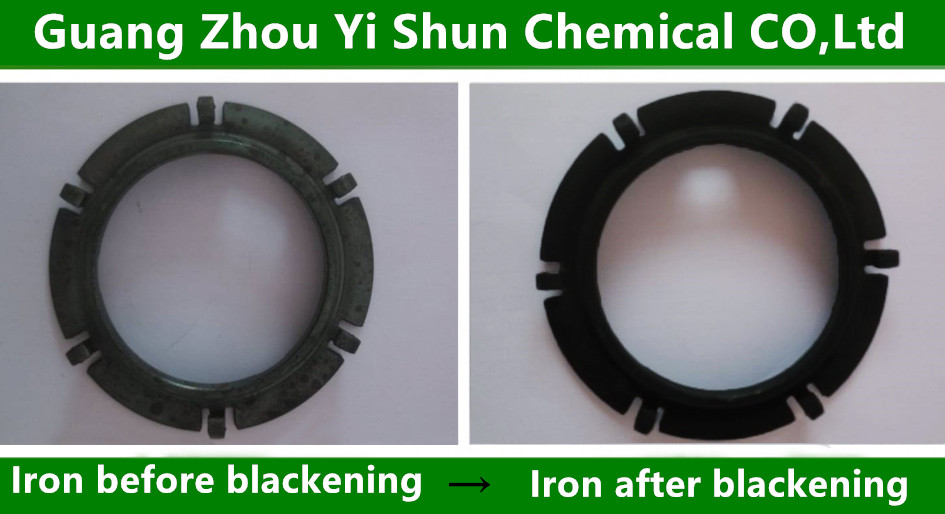

Product Nameú║Bright black high temperature steel blackening agent úČBlackening agent for metal parts úČ steel rust-proof blackening agent úČ stainless steel protective agentúČMetal sealer úČ High temperature blackening solution

Priceú║

Bright black high temperature steel blackening agent úČBlackening agent for metal parts úČ steel rust-proof blackening agent úČ stainless steel protective agentúČMetal sealer úČ High temperature blackening solution Bright black high temperature steel blackening agent úČBlackening agent for metal parts úČ steel rust-proof blackening agent úČ stainless steel protective agentúČMetal sealer úČ High temperature blackening solution First, the product code: Q / YS.310 (Yi Shun brand) Second, product performance: This product is suitable for all kinds of low carbon steel, carbon steel surface blackening treatment. Black film adhesion, uniform and shiny. Third, product index: ó┘ Thick paste body, shake evenly before use and pour out. ó┌ Specific gravity> 1.2 ó█ 140-145 íŠ conditions, the original paste use. Fourth, the use of methods: ó┘The steel blackening agent (Q / YS.310) fully shake evenly, if necessary, cover the bucket upside down repeated shaking evenly, and then remove the uniform blackening agent, heated to 140-145 íŠ on the electric furnace. ó┌Steel parts soaked in 20% hydrochloric acid rust 1- minutes, and then washed. ó█Immediately immersed in the blackening agent 140-145 íŠ, turning the workpiece from time to time. ó▄Black 5-10 minutes, remove the workpiece, immediately put into about 100 íŠ hot water, cleaning (in the middle do not stay, wash immediately). óŢImmersed in 180 íŠ transformer oil, dehydration and sealing oil treatment. óŮ Follow-up treatment. Fifth, note: ó┘ After degreasing rust iron pieces to be washed, immediately to black, the middle do not have to stay. ó┌ Black 5-10 minutes later, use about 100 íŠ hot water immediately for cleaning, the middle do not have to stay. ó█ If the pot of medicine precipitation, please stir well before use, does not affect the use of results. ó▄ Products are corrosive, please pay attention to protection work. Other processingú║Iron and steel surface treatment agent seriesíóAluminum Antique AgentíóCast Aluminum Cleaning AgentíóEnvironmental protection chemical plating nickel liquid (super-concentrated)íóBrass dedicated blackening Agent

|

Chinese

Chinese English

English