Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

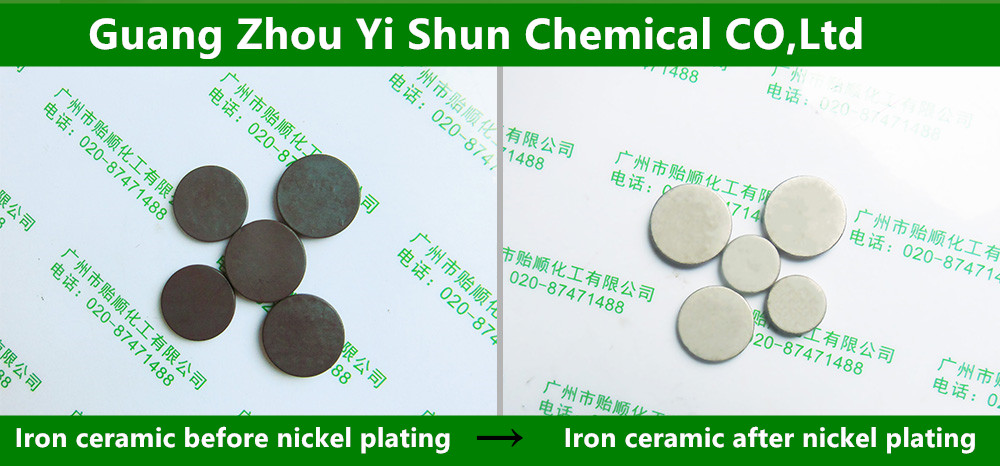

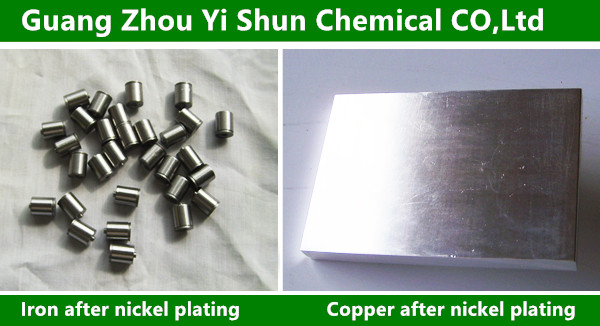

Product Name:Environmental protection chemical plating nickel liquid (super-concentrated),environmental nickel plating liquid , Rapid chemical nickel plating on metal and nonmetallic surfaces

Price:

Environmental protection chemical plating nickel liquid (super-concentrated),environmental nickel plating liquid , Rapid chemical nickel plating on metal and nonmetallic surfaces Environmental protection chemical plating nickel liquid (super-concentrated),environmental nickel plating liquid , Rapid chemical nickel plating on metal and nonmetallic surfaces First, the product code: Q / YS.602 (Yi Shun brand) Second, product features: The chemical nickel plating liquid is suitable for iron, steel, zinc alloy, zinc-treated aluminum alloy and copper alloy surface nickel-plated alloy layer. This product is non-toxic, environmentally friendly. No plating equipment. Just thermostat device, the coating is bright nickel-phosphorus alloy layer, excellent corrosion resistance, excellent adhesion strong bath stability, life expectancy more than 12 cycles This product is not only suitable for metal surface nickel (such as: iron, stainless steel, aluminum, copper, etc. , the same applies to non-metallic nickel plating, and does not require expensive palladium, low cost, such as: ceramic nickel, glass nickel, diamond nickel, carbon nickel, plastic nickel, simple, low cost, does not require plating equipment. Third, the product composition: This products make up of A agent, B agent and C agent, A and B ratio of 1: 4 to open the cylinder, with a ratio of 1: 1 and C added as an intermediate supplement. Fourth, open cylinder preparation and use of agents: ① with A agent and B agent with water, with the ratio of A: B: water = 0.5: 2: 7 = 1: 4: 14. ② with pure water to clean the plating tank. Then add half the size of the tank to the tank pure water. ③ first B agent proportionally added to the tank Stir, while stirring slowly add A agent. ④ 10% ammonia water to adjust the PH value to 4.7 ± 0.2. ⑤ Add deionized water to the specified volume. ⑥ heating bath bath temperature stable at 90 ℃ ± 3 ℃. Fifth, the operation process: ①Pre-treatment: the coating quality is essential, to make the surface of the workpiece before plating no pollution, and is in an activated state, this process are: degreasing, rust, polishing, washing. ② pickling activation: pickling activator soak the workpiece with 2-3 minutes, and then washed. ③ rinse the workpiece with hot deionized water, the workpiece temperature, in order to avoid the next plating, the cold work cooling bath to absorb heat and lead to stop plating. ④ in accordance with 0.5-1.5dm2 / liter loading than hanging suspension in the bath, bath temperature control at 90 ℃ ± 3 ℃, the use of time> 5 minutes, depending on the thickness may be. ⑤ plating process should be mild light mixing, the temperature and bath evenly distributed, so as to ensure the stability of chemical nickel plating, and the consistency of the coating at the same time, the bath should be recycle filter mesh: aperture 1- 8 Micron, resistant to 100 degrees Celsius, acid. ⑥ nickel plated with hot water to be completed, if necessary, can be passivated. Sixth, the maintenance of chemical nickel plating: ① in the plating process, because of the constant consumption of ingredients, plating speed will slow down, according to the number of bubbles to add supplements A and C, according to A: C = 1: 1 added. A small amount of time to When up for every consumption of one gram of nickel metal, need to add A and C of 10 ml each. When a large number of supplements A and C, the first cooling stop, then add A, C supplements and stir, in order to carry out nickel plating ②plating process, the bath pH value will change, the fresh bath pH control in 4.7-4.8, with the bath aging, PH value will slowly rise. ③ for the copper and nickel alloy surface to use clean wire or aluminum wire and copper parts in contact with the lead. ④ plating process to the bath often analysis test: PH value and nickel ion content. ⑤ pre-chemical nickel plating to undergo rigorous pre-treatment, to ensure that the workpiece surface in a clean and active state. ⑥ regular testing equipment: automatic temperature control system, circulating filtration system, timely detection and timely exclusion. ⑦ bath loading ratio to be controlled at 0.5d㎡ -1.5d㎡. Nickel detection method: Take 5.00ml plating solution into a 500ml flask, add 100ml of deionized water, then add 100ml of ammonia, add carbamate indicator. With 0.05mol / L of EDTA titration from orange to purple as the end point, the volume of milliliters consumed EDTA is recorded as V. Formula: Nickel (g / L) = 0.587 * V Other processing:Chemical Plating Liquid Train、Environmental degreer and rust remover、Brass Green Chemical polishing Agent、Electroless plating of real gold on copper surface、Strong oil stain removal agent、Copper、chromium and nickel stripping agent

|

Chinese

Chinese English

English