Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

Product Name:Brass Green Chemical polishing Agent,Metal cleaning Agent,Copper Protective Agent

Price:

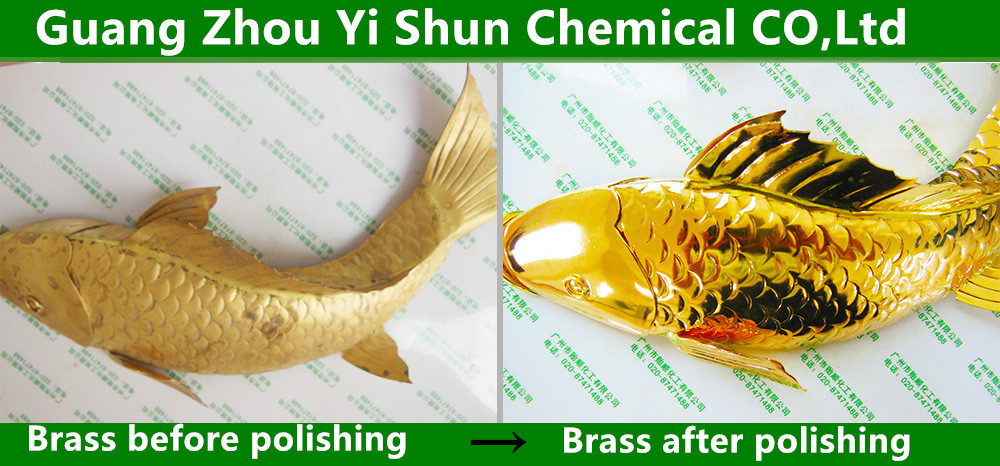

Brass Green Chemical polishing Agent,Metal cleaning Agent,Copper Protective Agent, Brass Green Chemical polishing Agent,Metal cleaning Agent,Copper Protective Agent First, the product code: Q / YS.103 (Yi shun brand) Second, the product range: This product is suitable for brass, copper (copper) and beryllium copper, tin bronze, phosphor bronze surface finish. Third, the advantages of this product: 1, the effect is stable and long. 2, the operation basically no yellow smoke, is an environmentally friendly products. 3, polished copper color, surface smooth, you can achieve the mirror effect. 4, low cost and extremely long service life. 5, due to the long-acting additive delivery, the service life of the product is greatly enhanced, making full use of the polishing agent, the effect is more than three times of similar products, the polishing effect is in the leading international level. Fourth, physical and chemical indicators: 1, the copper polishing agent is acidic. 2, the proportion: 1.446-1.45 3, the product was yellowish transparent. 4, this product does not add any heavy metals and nitrous acid and other harmful substances. 5, long-acting additives yellow, without any heavy metals and harmful substances. Five, use method: 1, the use of this product stock solution, can not add water to the polishing liquid, room temperature 20-35 ℃ use. Polished copper surface before the workpiece can not have oil. 2, polishing operation: The copper pieces are all immersed in the polishing liquid, soak for about 30 seconds -2 minutes after removal, rinse immediately with water rinse the copper on the polishing solution. One-time do not put too much workpieces, there must be a certain distance between the workpieces and workpieces, do not overlap between the workpieces, and flip the workpieces gently and polish occasionally, the purpose is to polish evenly. 3, whenever the use of a certain time, such as found brightness decreased, then add a long-acting additive, add 10 grams per kilogram of polishing agent ~ 15 grams of long-acting additives, mix evenly before use. 4, cleaned and air dried to the next step operation, such as passivation, welding and so on. Six, matters needing attention: 1, this product is acidic, corrosive to the skin, gently handle the operation, and wear rubber gloves. If inadvertently contact with the skin, rinse immediately with water. 2, the use of stock solution, use to avoid water into the polishing solution. 3, the product should be sealed before and after use, do not expose, store in a cool and ventilated place. Other processing:Chemical Plating Liquid Train、Dedicated copper plating liquid for aluminum、Chemical silver plating liquid (copper substrate)、Stainless steel chemical thicker liquid copper plating、Copper rust remover and degreasing agent

|

Chinese

Chinese English

English