Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

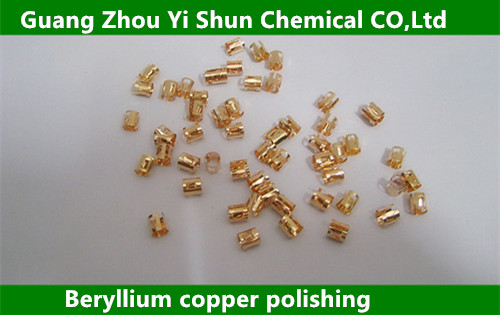

Product Name:Beryllium Copper Chemical polishing agent,Beryllium Copper Brightening Agent,Beryllium Copper pickling Polishing agent

Price:

Beryllium Copper Chemical polishing agent,Beryllium Copper Brightening Agent,Beryllium Copper pickling Polishing agent Beryllium Copper Chemical polishing agent,Beryllium Copper Brightening Agent,Beryllium Copper pickling Polishing agent First, the product code: Q / YS.102 (Yi Shun brand) Second, the scope of products: This product is suitable for the chemical polishing of beryllium copper. After the product is polished, the surface of the copper is very smooth and bright, full of copper character, and even specular reflection on the copper surface. Third, the product index: 1, the product is acidic. 2, the proportion of: 1.4-1.48. 3, Appearance: light yellow transparent liquid. Fourth, steps: 1, polishing operation is not allowed to bring water operation,if add water operation will affect the polishing quality. Please use the original liquid and ventilated place at room temperature operation. 2, the copper workpiece immersed in the copper polishing liquid, about 2-3 minutes after removing the copper pieces, immediately into the water for full flush, the workpiece on the medicine clean. 3, polished copper workpiece and cleaned to enter the next process, such as spraying, passivation, etc.In order to prevent the discoloration of copper parts again, the workpiece should be dried, passivation. 4, in the polishing process, when the copper gloss is found to meet the requirements should be added to the polishing liquid a small amount of long-lasting additives. Additional amount of 0.5% -1.0% of the original polishing liquid, add a small amount of additives should be added as well. When the polishing liquid color is dark green, if you still can not meet the requirements after adding long-acting additive, you should replace the new polishing agent for polishing. Fifth, note: 1, the product is corrosive, the operation should pay attention to protective measures, do not touch the polishing liquid with human skin, gently, to prevent splashing. 2, the working tank filled with polishing liquid plastic material is better, do not use metal, ceramic and other materials of equipment. 3, Please put the product in a cool and ventilated place to save. 4, polished to flip the workpiece, at the same time, you can not put too much workpiece in one time.There should be a gap between the workpiece and the workpiece. 5, fully clean, especially inside the pipe. Other processing:Environmental Copper、nickel removal liquidnew nickel deplating agent、Environmental degreer and rust remover、Stainless Steel Polishing Agentas、Brass Green Chemical polishing Agent、Electroless plating of real gold on copper surface、Strong oil stain removal agent、Stainless steel chemical thicker liquid copper plating

|

Chinese

Chinese English

English