Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

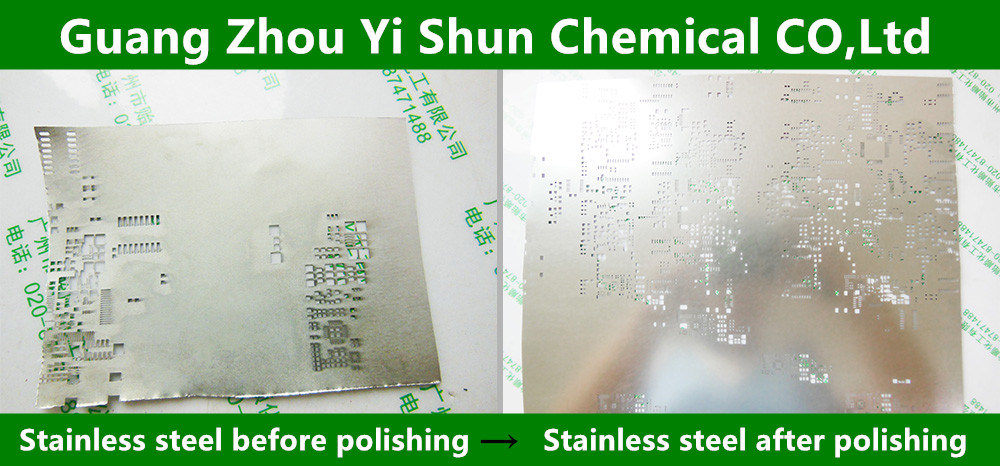

Product Name:Stainless Steel electrochemical Polishing agent,Stainless Steel electrolytic Polishing agent,Stainless steel Electro-polishing agent,Electrochemical polishing agent for die Steel

Price:

Stainless Steel electrochemical Polishing agent,Stainless Steel electrolytic Polishing agent,Stainless steel Electro-polishing agent,Electrochemical polishing agent for die Steel Stainless Steel electrochemical Polishing agent,Stainless Steel electrolytic Polishing agent,Stainless steel Electro-polishing agent,Electrochemical polishing agent for die Steel First,Product Code: Q/YS.309 (YiShun brand) Second, product advantages: This product does not contain heavy metals, does not contain hexavalent chromium electrochemical polishing agent, electrolytic polishing at low current and high temperature, can get bright as a mirror stainless steel, this product does not contain toxic and hazardous substances, environmentally friendly, applicable In 201#, 304#, 306# and other types of stainless steel Third, product indicators: 1 Specific gravity>1.20 2 PH<5.0 3 Odorless, light yellow transparent liquid Fourth, use method: 1 A stainless steel workpiece is used as the anode and a lead plate with the same area is used for the cathode. The spacing of the yin and yang plates can be controlled at about 1.5CM to achieve the best polishing effect. 2 This product is used as a liquid. It is forbidden to bring water into the polishing solution. The stainless steel before polishing must be degreasing and washed, and it must be allowed to dry before entering the electrochemical polishing agent. 3 working conditions: voltage 5-10 volts, anode current density 8-15A/dm2, polishing liquid temperature controlled between 75°C-95 °C, polishing time is 5-12 minutes. Five considerations: 1.Precipitates from the polishing process, periodically discard the sediment in the tank. 2.The distance between the two poles of Yin and Yang is about 1.5CM. 3.The polishing temperature is controlled between 75°C-95°C. Other processing:Chemical Plating Liquid Train、Chemical nickel plating liquid、Strong oil stain removal agent、Metal polishing Agent、Stainless steel chemical thicker liquid copper plating

|

Chinese

Chinese English

English