Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

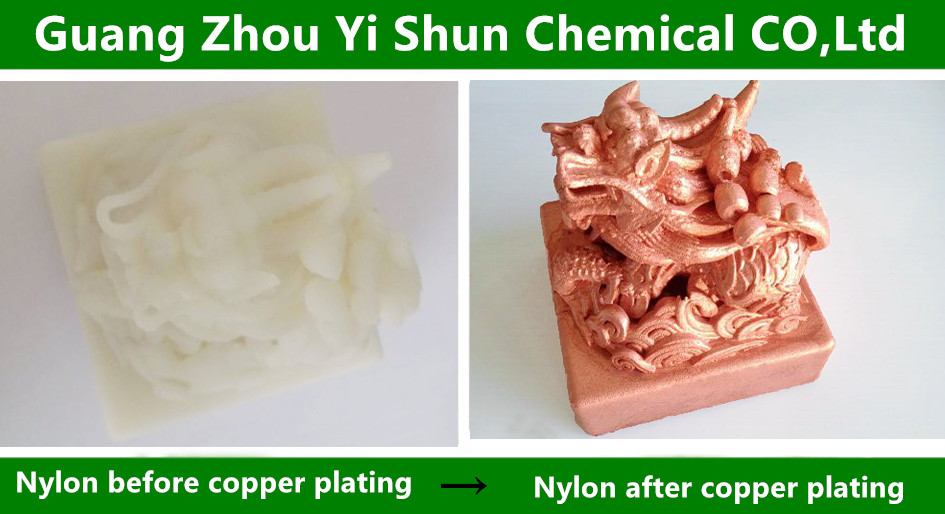

Product Name:Efficient and rapidly chemical copper plating liquid,Non-metallic high speed copper plating,Environmental protection copper plating liquid,a new chemical copper plating agent,Non-cyanide environmental chemical copper plating water

Price:

efficient and rapidly chemical copper plating liquid,Non-metallic high speed copper plating,Environmental protection copper plating liquid,new chemical copper plating agent,Non-cyanide environmental chemical copper plating agent Efficient and rapidly chemical copper plating liquid,Non-metallic high speed copper plating,Environmental protection copper plating liquid,a new chemical copper plating agent,Non-cyanide environmental chemical copper plating water Ⅰ.The product code: Q / YS.118 (Yi Shun brand) Ⅱ. Product performance: This product has high-speed sinking copper, high stability, working height and solution concentration for a wide range of applications. Copper layer is dense, with excellent bonding, the coating is bright copper color, plating speed of 25 microns / hour at 50 ℃. Ⅲ.The product scope: This product is suitable for printed circuit board hole metal, aluminum, iron, copper, stainless steel and copper alloy surface copper plating, suitable for hanging baskets chemical plating. Also suitable for ceramic copper plating, glass copper plating, resin copper plating, plastic copper plating, diamond copper plating, leaf copper plating, etc., a very wide range of uses, you can barrel plating. Ⅳ. Product index: 1.High-speed copper sink agent A agent: specific gravity 1.10 1.12, blue liquid, 2.Shen copper B agent: Specific gravity: 1.10 1.12, transparent liquid. PH value of 13 14, C agent is a colorless transparent liquid. 3.Preparation of copper working solution: press before using A: B deionized water 1: 5: 5 (Note: clean tap water can be) After heating to 50℃, add 3 ml of ¼ per kilogram of copper working solution and mix well. A. For the iron surface and the nickel surface and silver surface copper plating, just pickling rust can be used for copper. B. For the zinc alloy surface, the zinc polish or zinc degreasing agent should be used for degreasing and bright treatment first, then thickening copper plating using this product (Q / YS.118). C. For stainless steel, degreasing first with hydrochloric acid for 3 minutes, and then use the company's special stainless steel copper plating liquid(Q / YS.129) pre-plated copper, then the use of copper plating liquid (Q / YS.118) padded copper. D. For non-metallic (ceramics, glass, diamonds, sand, etc.) should be roughened → sensitization → hot water washing → activated → washed → copper plating; can also be roughened → activation → nickel → re-copper plating. Ⅴ.Note: 1.Copper sinking process will continue to consume ingredients, copper sinking process should be timely replenish A, C agents and sodium hydroxide, test and adjust the PH value to 12.5 13.0. (Adding A agent with stirring, adding 50% sodium hydroxide and sodium hydroxide solution slowly) 2.Copper loading than 13d square meters, sinking copper temperature: 50 ℃ ± 5 ℃, water bath insulation. 3.Chemical copper sink to stop working, stop adding ¼ agent and sodium hydroxide, to be covered, to prevent loss of active ingredients bath reactive loss and insect dust pollution. Restart the bath, filter copper plating solution A additional amount of agent, with stirring under the conditions of NaOH solution to adjust the PH value of 12.5 13.0, heated to 50 ℃, and then add C agent, the additional amount of 3 ml / kg . 4.In the process of sinking copper if you find the bath becomes turbid, this time to stabilize 0.5 g / liter. Stir the bath back to stability. 5.Copper after the end, to be washed with water, and then 80 ℃ -90 ℃ hot water soak for a few minutes cleaning, and timely follow-up treatment, such as passivation or plating other metal layer. Especially for porous materials, it should be cleaned several times, and thoroughly washed with hot water to ensure the smooth follow-up work, such as ceramics, wood, cotton cloth materials. 6. The whole process of controlling the content of copper (Cu2 +) element 5.5-6.5g / liter, copper temperature control at 45-55 ℃, C agent a small amount of multiple replenishment, control agent C agent 3 ml / kg. 7.Additional process of copper hydroxide solution, each additional amount of 1-3 grams / kg. A dose of 10 ML / kg. Open the cylinder for example:

Other processing:Chemical Plating Liquid Train、Zinc coating imitation gold agent、Chemical silver plating liquid (copper substrate)、Stainless steel chemical thicker liquid copper plating

|

Chinese

Chinese English

English