Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

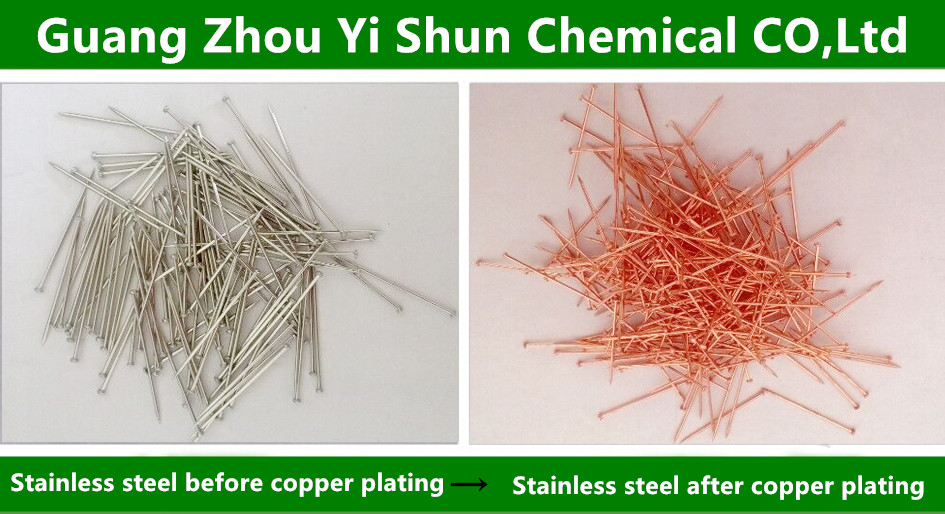

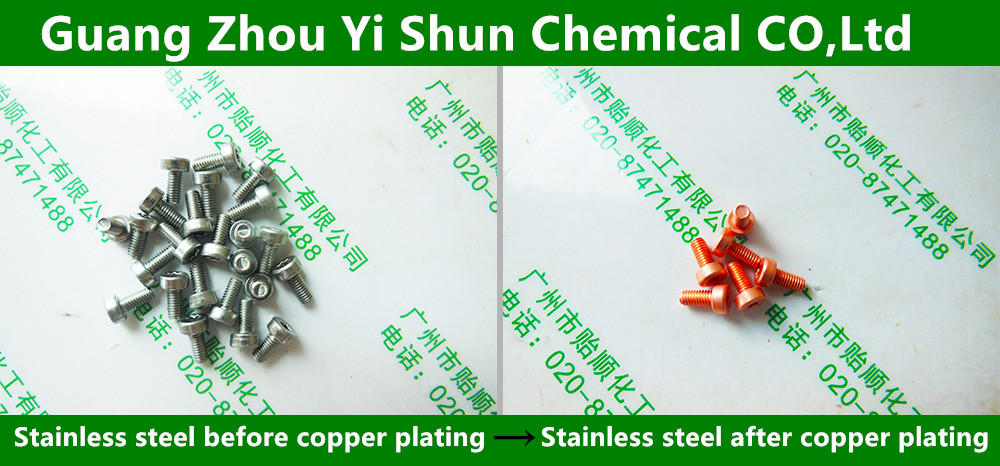

Product Name:316# stainless steel dedicated copper plating liquid , environmental dedicated copper plating liquid ,stainless steel copper plating liquid ,water pipe copper plating liquid , technological copper plating agent ,

Price:

316# stainless steel dedicated copper plating liquid , environmental dedicated copper plating liquid ,stainless steel copper plating liquid ,water pipe copper plating liquid , technological copper plating agent , 316# stainless steel protective agent , Stainless steel special sink copper liquid, Copper-plated potion , Electroless copper plating formula 316# stainless steel dedicated copper plating liquid ,environmental dedicated copper plating liquid ,stainless steel copper plating liquid ,water pipe copper plating liquid , technological copper plating agent First, the product code: Q / YS.131 (Yi Shun brand) Second, the scope of products: This product is suitable for chemical copper plating on 316 # stainless steel surface. The surface after copper plating is bright copper color. The coating has good bonding force and can provide a solid foundation for thickening copper plating or nickel plating in the next step. Third, product index: 1, transparent acid liquid; 2, product stock solution use 3, the temperature of copper plating is 60 ℃ -80 ℃; 4, copper plating time is 10-15 seconds. Fourth, product use method: 1,316 # stainless steel pretreatment: degreasing, polishing and so on; 2,immersed in 15-20% hydrochloric acid solution for about 20-30 seconds; 3, immediately after washing into the preheated to 60 ℃ -80 ℃ 316 # stainless steel for copper plating liquid for about 10-15 seconds, immersion process to flip the workpiece, the coating evenly. (Note: This product heating method: water bath heating, plastic containers); 4, immediately after washing to do the next step, such as chemical nickel plating, chemical copper plating thickening or electroplating. Fifth, note: This product in the middle of the use of supplemental additives to be timely, 1-2 g / kg, in order to maintain the stability of the working fluid. Other processing:Chemical Plating Liquid Train、Zinc coating imitation gold agent、Chemical silver plating liquid (copper substrate)、Stainless steel chemical thicker liquid copper plating

|

Chinese

Chinese English

English