Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

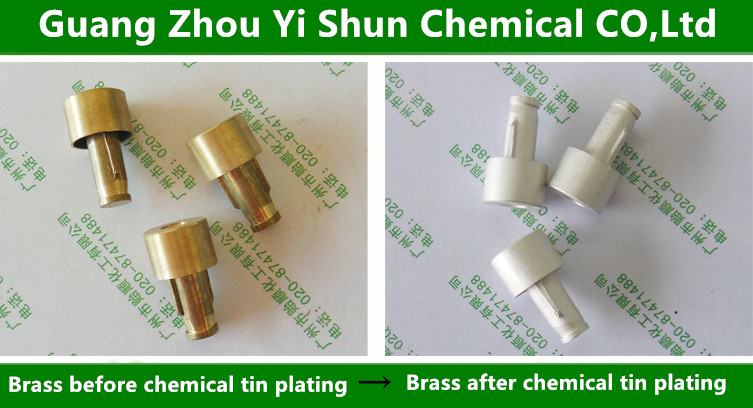

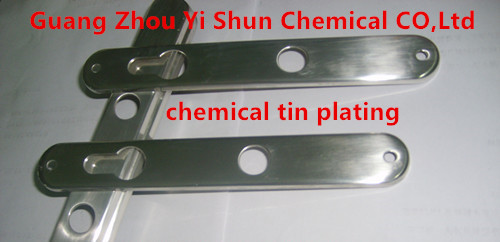

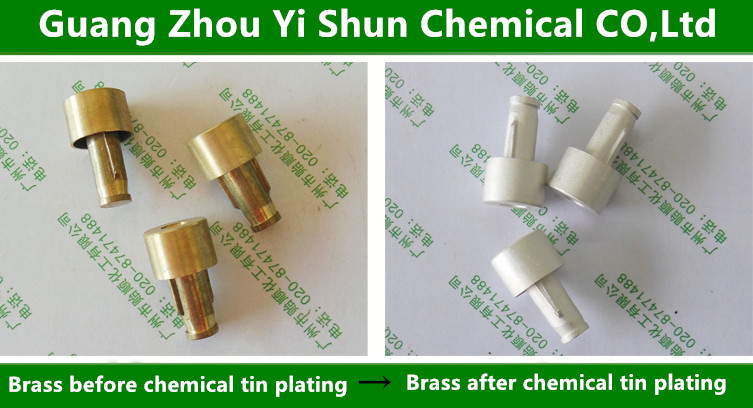

Product Name:Chemical tin plating liquid ,anti-oxidation tin plating agent ,new nontoxic environment-friendly ,Copper surface tin plated , Electronic components tin plated liquid

Price:

Chemical tin plating liquid , anti-oxidation tin plating agent , chemical water used for sink tin , High quality chemical tin plating liquid , new nontoxic environment-friendly , Copper tin plating process , Tin plating on copper , Copper surface tin plated , Tin protective agent , Electronic components tin plated agent Chemical tin plating liquid ,anti-oxidation tin plating agent ,new nontoxic environment-friendly ,Copper surface tin plated , Electronic components tin plated liquid

First,Product number:Q/YS.402(Yi Shun brand) Second,product features: Products can be used for chemical tin plating on the surface of copper, brass, copper beryllium copper alloy, tin coating is bright and silvery white, can increase the copper welding and the decoration, does not affect the conductivity, It is suitable for the electronics industry, appliances, furniture, food packaging. It is Anti oxidation, non-toxic,non heavy metal, and make product perfect appearance. Salt spray test is more than 45 hours without rust. soak without plating equipment. Third, product index: 1. Proportion :1.04-1.05 2. PH:1.0-1.2 3. Appearance:colorless transparent liquid Fourth, chemical tin plating process: Copper pieces removal of oil→pickling or (polished) or (sandblasting) →two step washing → chemical tin plating →three step washing →dry with cold wind→ the detection. Tin chemical tin plating: add 1 times water and 8-10g/kg Tin plating additive into this working liquid. Tin temperature :at room temperature of 20 DEG C to 35 DEG C, time :5-8 minutes, lightly stir work liquid or gently flip the work piece. Fifth, matters needing attention: In order to prevent the copper surface from re-oxidation and affect the quality of the coating, the copper work piece should be put into the tin bath in time. Sixth, Product supplement in the midway: When the tin plating efficiency decreases, you can add 1% o tin plating additive and stir evenly to use. Other processing:Chemical Plating Liquid Train、Zinc coating imitation gold agent、Chemical silver plating liquid (copper substrate)、Stainless steel chemical thicker liquid copper plating

|

Chinese

Chinese English

English