Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

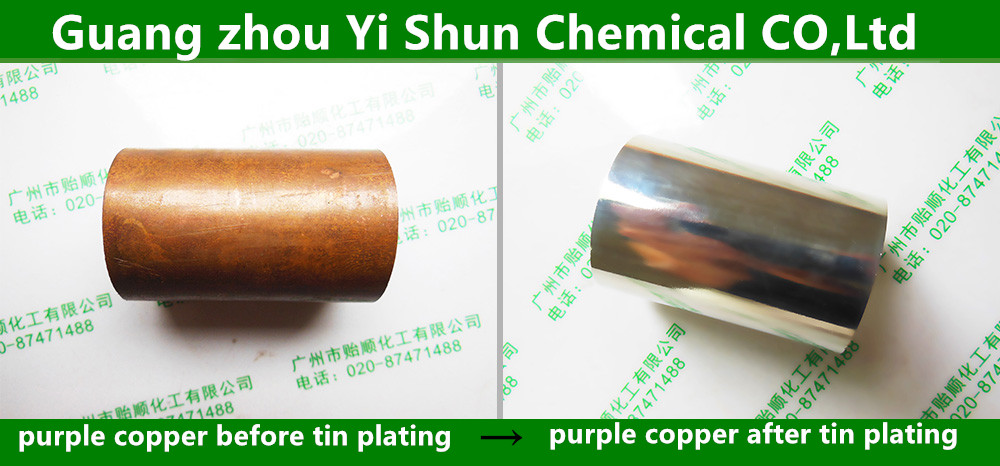

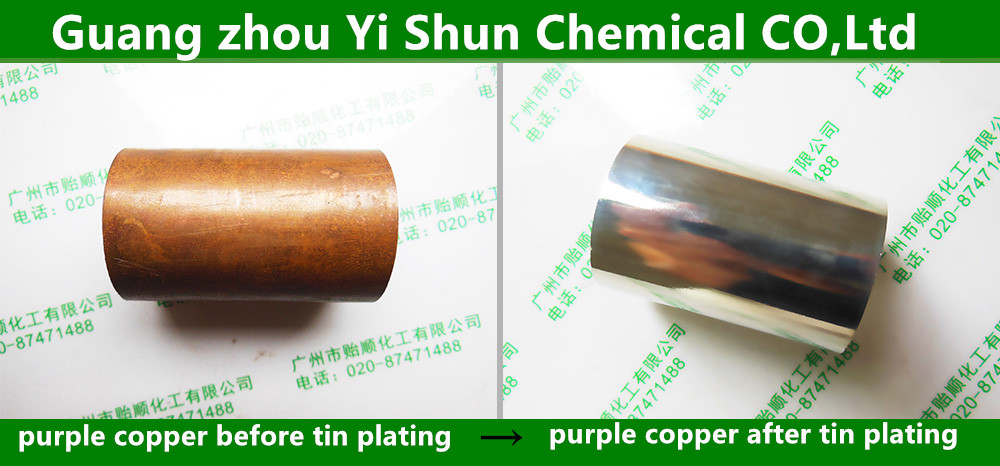

Product Name:Chemical plating thick tin liquid (copper substrate) ,Copper pieces chemical tin plating ,Environmental chemical tin plating , Tin plating brightening agent,Metal surface tin plating

Price:

Chemical plating thick tin liquid (copper substrate),copper pieces chemical tin plating ,environmental chemical tin plating , Tin plating brightening agent,metal surface tin plating, Tin plated on copper Chemical plating thick tin liquid (copper substrate) ,Copper pieces chemical tin plating ,Environmental chemical tin plating , Tin plating brightening agent,Metal surface tin plating First, the product code: Q / YS.402-2 (Yi Shun brand) Second, product features: The products can be used for chemical tin plating on copper alloy surfaces such as copper, brass, beryllium copper and the like. The tin coating is semi-bright silver white, which can meet the welding and decorative properties of copper without affecting the conductivity and can be used in the electronics industry, furniture, food packaging and so on. Anti-oxidation, increase the appearance of copper artifacts, non-toxic products without heavy metals, salt spray test more than 45 hours does not rust. No plating equipment, just soaking, easy and simple, thick tin plating, tin layer thickness of 20um or more, fully meet the requirements of brazing. Third, product index: ① proportion: 1.04 ~ 1.05 ② PH: 1.0 ~ 1.2 ③ Appearance: light yellow liquid Fourth, the chemical tin plating process: copper degreasing → pickling or (polishing) or (sandblasting) → two washing → chemical tin plating → three washed → timely with cold air drying → testing. Remove oil, polishing, pickling → Heating chemical tin plating solution (402-2) to 50 ℃ -60 ℃ → Join 20g / KG tin additive and stir well → Immersion of copper workpiece for 8-20min → Washing, drying at 60 ℃ → Finished product Fifth, note: 1, After the copper parts washed into the tin plating solution in a timely manner to prevent oxidation of the copper surface again affect the quality of the coating. 2, The use of liquid products, do not add water. Sixth, the product half-way to add: When the tin-plating efficiency drops, add 1.0% of tin plating additives, stir and continue to use. Other processing:Chemical Plating Liquid Train、Zinc coating imitation gold agent、Chemical silver plating liquid (copper substrate)、Stainless steel chemical thicker liquid copper plating、Copper oil removal passivation agent

|

Chinese

Chinese English

English