Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

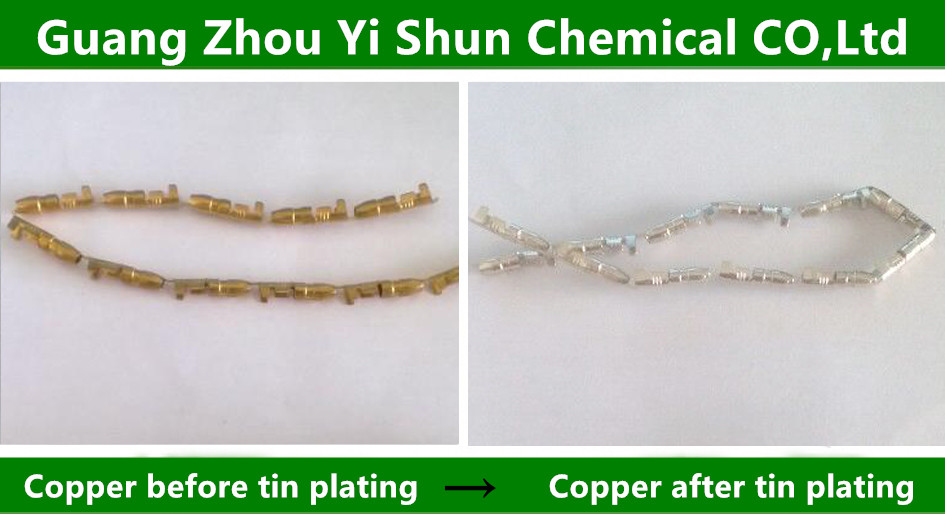

Product Name:Environmental electric brush tin plating solution(bright type) , Tin plating proctive agent that use electricity ,Bright tin plating solution , Tinned brightener formula

Price:

Environmental electric brush tin plating solution(bright type) , Environmental tin liquid that use electricity ,Environmental protection elector brush solution for sinking tin, tin plating proctive agent that use electricity ,Bright tin plating solution , Tinned brightener formula , The role of copper tin plating Environmental electric brush tin plating solution(bright type) , Environmental protection metal surface treatment of detin solution , Tin plating proctive agent that use electricity ,Bright tin plating solution , Tinned brightener formula First, product number:Q/YS.408(Yi Shun brand) Second, product advantage: This products are widely used for brush a layer of bright and silvery white tin plating layer for various types of copper, iron, nickel and other metal surface, simple operation, coating is dense , good adhesion, no waste and loss operation in the process of plating solution, the coating has good corrosion resistance, is not easy to change color, odorless, non-toxic, environment friendly, compliant with the requirement of green environmental protection, It is used for good brazing layer and the conductive layer and also be used to fill the scratch , improve the lubrication performance, improve wear resistance and improve the sealing performance of the work piece, etc. You can also use anti-nitrided coating. Third, product index: 1.Product appearance: odorless,light yellow liquid 2.Proportion:﹥1.0 3.The tin content is more than 40g/KG 4.brush movement speed: 30cm ~ 60cm/ seconds 5.Brush plating voltage: 8 ~ 11 Volts Fourth, usage method: 1.The work piece before processing: rust removal, polishing electric net, activation, get the clean surface. 2.A clean brush plating dip in tin plating liquid (Q/YS. 408), the voltage is adjusted to 8 ~ 11 v. use lower voltage at the beginning of brush plating , then slowly increase the voltage. 3.Brush plating on the surface of the work piece at a rate of 30cm ~ 60cm/ seconds and uniform plating to obtain silver and bright tin coating. 4.Rinse the plated work piece with clean water and dry timely,if washing and drying after passivation, the effect is better. Fifth, matters needing attention: 1.This product is brush electroplating tin bath, non-contaminated by other metal ions, no iron, copper, zinc and nickel plasma into. 2.It is forbidden for mixing with other chemical substances, or they will lose their original advantages, avoid the pollution of acid and alkali salt and other compounds. 3.Brush plating (or plating pen) cannot be used together, one brush only can use a kind of brush plating solution. Other processing:Chemical Plating Liquid Train、Zinc coating imitation gold agent、Chemical silver plating liquid (copper substrate)、Stainless steel chemical thicker liquid copper plating、Copper oil removal passivation agent

|

Chinese

Chinese English

English