- Chemical Plating Liqui¡

- Environmentally friend¡

- Copper surface treatme¡

- Aluminum surface treat¡

- Iron and steel surface¡

- Tin surface treatment ¡

- Zinc surface treatment¡

- Nickel surface treatme¡

- Industrial cleaning ag¡

- Domestic cleaning agen¡

- Magnesium surface trea¡

- Other metal surface tr¡

- Other

Tax Registration Number: 91440101552358350G

Bank:BANK OF CHINA GUANGZHOU ZENGCHENG ZHONGXIN SUB-BR

Account :705569418477

E-mail: gdyshg@163.com

Tel: 15118868698 020-87471488

Business address:The new town of Zengcheng District of Guangzhou Ctiy in Cunjing Fung pui road 30

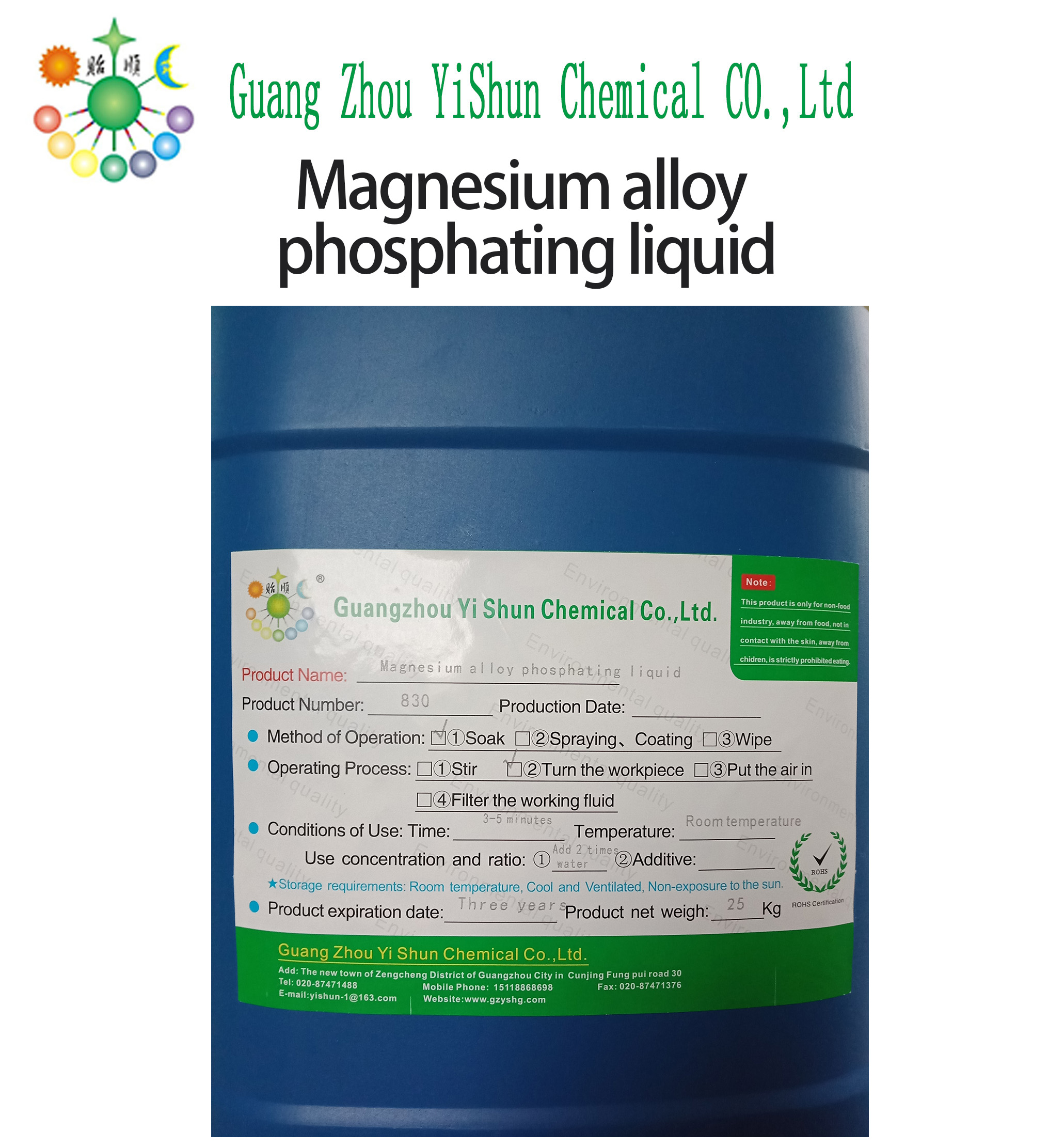

Product Name£ºMagnesium alloy phosphating liquid£¬Environmental protection phosphating liquid£¬Antirust phosphating solution£¬Phosphating blackening agent

Price£º

Magnesium alloy phosphating liquid£¬Environmental protection phosphating liquid£¬Antirust phosphating solution£¬Phosphating blackening agent£¬Normal temperature phosphating liquid of magnesium alloy Magnesium alloy phosphating liquid£¬Environmental protection phosphating liquid£¬Antirust phosphating solution£¬Phosphating blackening agent product number: Q/YS.830 (yishun brand) Application: Magnesium alloy is a kind of active metal, which is easy to moldy and rot. After the company production of magnesium alloy magnesium alloy phosphating agent, can be generated on the surface of a film of corrosion resistance is very good, can improve the adhesion strength of the magnesium alloy surface with paint, at the same time can also be used for the next process (such as chemical nickel plating, electroless plating copper) before processing, improve the bonding strength, product environmental protection, heavy metal and harmful substances Product indicators 1. The product is odorless and transparent; 2. PH value less than 7.0, weakly acidic; 3. Specific gravity > 1.0. Usage: 1. Prepare clean plastic buckets (PP, PE, PVC, etc.), and add twice tap water (purified water is better) into magnesium alloy phosphating agent to form working liquid 2. Immerse the oil-free magnesium alloy in the working liquid of phosphating agent at room temperature for 3-5 minutes, and flip the workpiece in the process to change the position of the workpiece. 3. Wash with water for 3 times 4. Dehydrate and dry the workpiece. matters needing attention: Use process, do not contact with the skin. (2) midway loss to add in time. Other processing£ºMagnesium surface treatment agent series¡¢Metal coloring agent¡¢High efficiency deplating agent¡¢Metal polishing Agent¡¢Environmental degreaser and rust remover¡¢Yellow passivating agent for magnesium alloy

|

Chinese

Chinese English

English